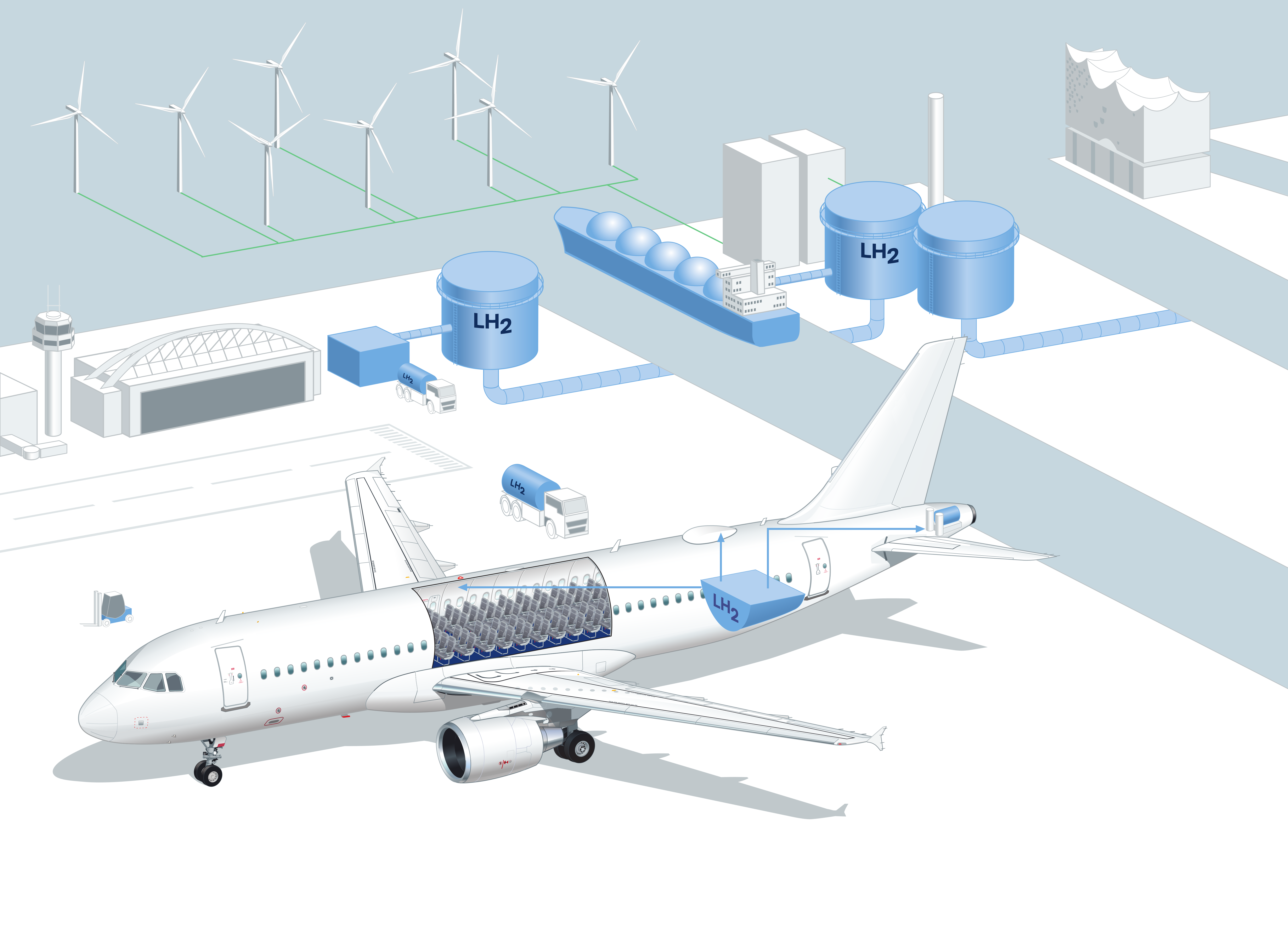

The aerospace industry in Hamburg is preparing for flying with hydrogen. From October 2022 to 2024, Lufthansa Technik, with financial support from the City of Hamburg, will work with the German Aerospace Center (DLR), the Center of Applied Aeronautical Research (ZAL) and Hamburg Airport to develop and test extensive maintenance and ground processes using hydrogen technology. For this purpose, an aircraft of the Airbus A320 family will be converted into a stationary laboratory at Lufthansa Technik’s base in Hamburg. Within this lab, the partners want to test the effects of Liquid Hydrogen (LH2) on maintenance and ground processes.

The project has reached a new milestone

Lufthansa Technik has prepared the aircraft – which flew for Lufthansa Group for 30 years as "Halle an der Saale" – for its crucial next stage. Over the next few months, the Hydrogen Aviation Lab will be fitted with a full suite of test systems as well as an internal tank for liquid hydrogen and an onboard fuel cell, paired with supporting ground-based hydrogen infrastructure.

You are about to play a YouTube Video, if you confirm you accept the external YouTube resources.

The Inside Sessions (Season 3 Episode 4) | Hydrogen and its potential in aviation

The Inside Sessions (Season 3 Episode 4) | Hydrogen and its potential in aviation

With the Hydrogen Aviation Lab, the project partners want to prepare for handling and maintenance of hydrogen-powered aircraft, whose entry into service is forecast for the middle of the next decade. Yet the laboratory will also spur on developers of future hydrogen-powered aircraft generations by helping optimise the procedures and safety levels during maintenance work or ground-handling.

A particularly striking example is refuelling with liquid hydrogen (Liquid H2, or LH2 for short). Using current technology, the refuelling for a long-haul flight could possibly take several hours. Given the pressure on aircraft turnaround times in the airline industry, this would be clearly impracticable. The Hydrogen Aviation Lab is designed to address this and many other areas of research.

Digital twin

Parallel to research carried out using the physical hardware of the Hydrogen Aviation Lab, the project also involves the creation of a so-called digital twin of the Airbus A320. Therein, simulations will enable researchers to develop and test predictive maintenance methods for the systems and components of future aircraft generations. Using targeted data analyses, failures of hydrogen components and systems could thus be predicted ahead of their failure in the physical system, allowing timely replacements before component failures affect aircraft operation.

Potential for future generations of aircraft

Green Hydrogen is a much more sustainable option in comparison to common kerosene and fosters a potential for future generations of aircraft. For that, the platform offers many options to investigate the effects as a physical and virtual demonstrator – also for the future. Furthermore, the positioning of Hamburg as a hydrogen economy is a further goal of the partners to assure an international lead and standing.